This summer we decided to hit the road and see how many letterpress shops we could visit in a week. Thanks to our friends at Firecracker Press, we have a handy Letterpress Trail map, which is an attractive way to keep track of our stops.

We drove down through Indianapolis to Nashville to visit our friend Celene at Hatch Show Print, one of the oldest letterpress shops in the country. It is now housed in an incredible new venue as part of the Country Music Hall of Fame, and includes a gallery and retail space as well as the actual shop.

We drove down through Indianapolis to Nashville to visit our friend Celene at Hatch Show Print, one of the oldest letterpress shops in the country. It is now housed in an incredible new venue as part of the Country Music Hall of Fame, and includes a gallery and retail space as well as the actual shop.

Jo and Celene messed around with some of the large wood cuts for historic posters.

Jo and Celene messed around with some of the large wood cuts for historic posters.

Check out the beautiful space. Hundreds of cases of types, a handful of presses and a whole lot of gumption (can you say 600 posters a year?)

Check out the beautiful space. Hundreds of cases of types, a handful of presses and a whole lot of gumption (can you say 600 posters a year?)

I took most of our photos at the end of the day so you don't get the buzz of a working shop, but it was indeed humming! Jim Sherradin was still around, working on oversized pieces for the gallery.

I took most of our photos at the end of the day so you don't get the buzz of a working shop, but it was indeed humming! Jim Sherradin was still around, working on oversized pieces for the gallery.

This is an amazing wall of wood type that measures over 20 line, or approximately 3.5".

This is an amazing wall of wood type that measures over 20 line, or approximately 3.5".

Jo got to hold this large wood type J, as well as hang with the shop cats, Huey and Maow.

Jo got to hold this large wood type J, as well as hang with the shop cats, Huey and Maow.

We had a fantastic time exploring Hatch, not to mention enjoying the tasty pulled pork that was on deck after the shop closed. Can't wait to visit again.

We had a fantastic time exploring Hatch, not to mention enjoying the tasty pulled pork that was on deck after the shop closed. Can't wait to visit again.

Our next stop in Nashville before heading out was to Isle of Printing. We're big fans because they are fellow Press Bikers, with a mobile station on wheels as part of their Our Town project. Check it out!

Our next stop in Nashville before heading out was to Isle of Printing. We're big fans because they are fellow Press Bikers, with a mobile station on wheels as part of their Our Town project. Check it out!

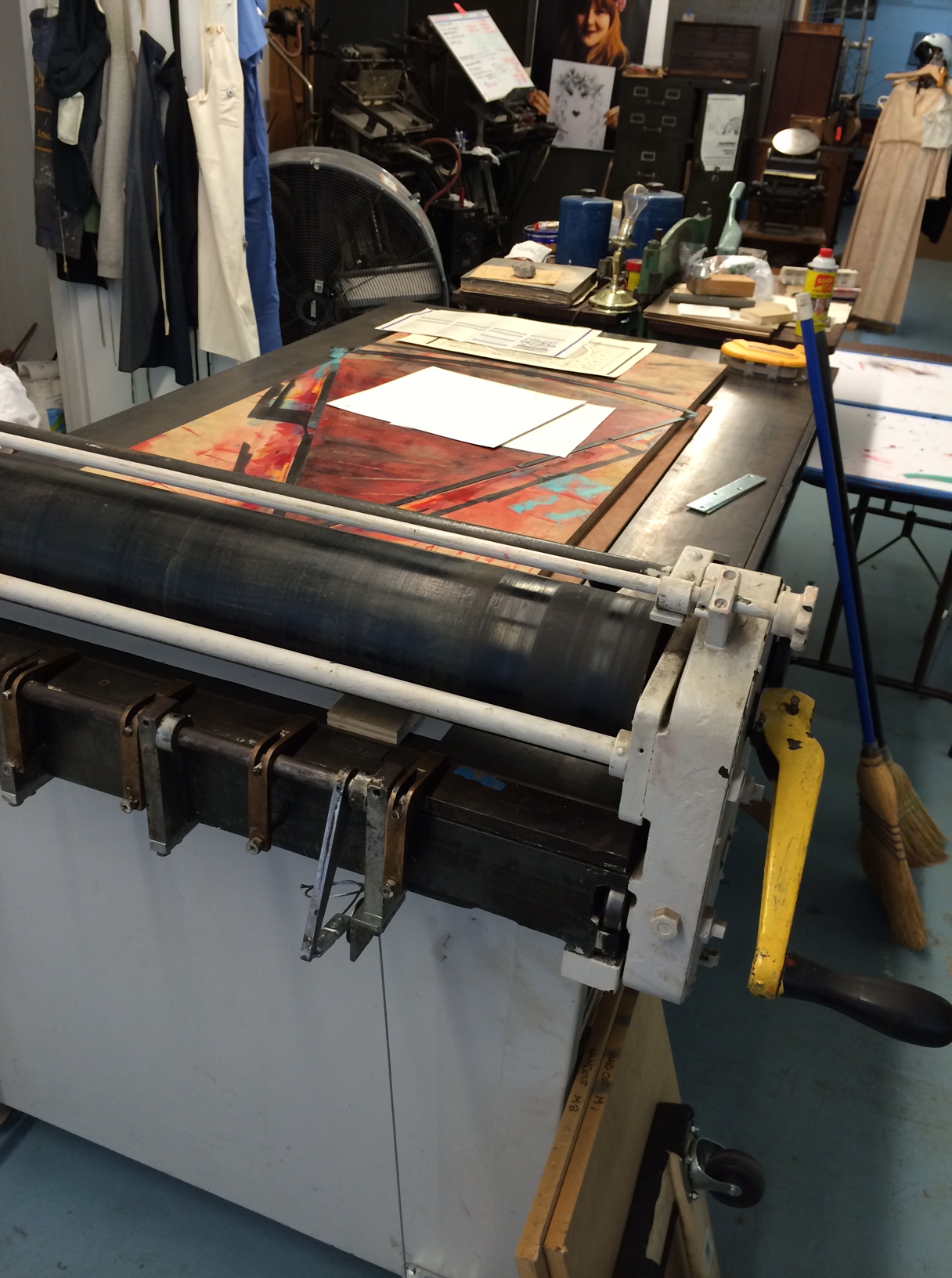

This giant press was used for a project we got to see on the outside of the building. Do you see something vaguely pie shaped?

They have a large shop with tons of space for printing as well as exploring their numerous public art projects that are taking over Nashville.

They have a large shop with tons of space for printing as well as exploring their numerous public art projects that are taking over Nashville.

And here are the pie shaped prints, pasted on the wall outside! One might think Jo coordinated her outfit for this shot with Bryce, the leader of the gang.

And here are the pie shaped prints, pasted on the wall outside! One might think Jo coordinated her outfit for this shot with Bryce, the leader of the gang.

After our stay in Tennessee we headed up to Cincinnati to visit Steam Whistle Letterpress, friends we made while at the National Stationery Show. Brian has a fantastic shop in the Over The Rhine area of the city, and makes some lovely, vintage-inspired prints and cards with metal type, wood and hand carved cuts, all things we can get behind.

After our stay in Tennessee we headed up to Cincinnati to visit Steam Whistle Letterpress, friends we made while at the National Stationery Show. Brian has a fantastic shop in the Over The Rhine area of the city, and makes some lovely, vintage-inspired prints and cards with metal type, wood and hand carved cuts, all things we can get behind.

We took the opportunity to pick up some great cards and talk shop. Brian's awesome business cards fold into actual steam whistles, and he paused a moment to show Jo how it worked. How's that for branding!

We took the opportunity to pick up some great cards and talk shop. Brian's awesome business cards fold into actual steam whistles, and he paused a moment to show Jo how it worked. How's that for branding!

Another friend we made at the Stationery Show was Maya from Visual Lingual. She is one half of the team that makes seed bombs, little portable gardens you can plant anywhere! We picked up a few sacks and can't wait to get them started. You can find their work all over Cincinnati as well as nationwide.

Another friend we made at the Stationery Show was Maya from Visual Lingual. She is one half of the team that makes seed bombs, little portable gardens you can plant anywhere! We picked up a few sacks and can't wait to get them started. You can find their work all over Cincinnati as well as nationwide.

And luckily for us, Maya pointed us to the American Sign Museum, a glorified warehouse full of signage from around the country that has been rescued from the dump and obscurity. This is a must stop for anyone interested in Americana, neon, sign painting and letterforms.

And luckily for us, Maya pointed us to the American Sign Museum, a glorified warehouse full of signage from around the country that has been rescued from the dump and obscurity. This is a must stop for anyone interested in Americana, neon, sign painting and letterforms.

We'll be back soon with Part Two of our Letterpress Trail, which picks up in Columbus!

We'll be back soon with Part Two of our Letterpress Trail, which picks up in Columbus!