I’m so excited to have a guest blogger this month! Val Lucas, of Bowerbox Press, has been learning the art of casting metal type and has written up her adventures to share here. Enjoy!

Have you ever wondered if anyone is still making new type? What about new designs? There are a handful of typecasters working in the US, and I was lucky enough to reconnect with one of them in the fall of 2021. I met Jim Walczak through my APHA printing group in 2007, and watched him casting type shortly after I had started learning about letterpress printing. Fast forward almost 15 years, and I took a trip to Massachusetts to cast a font of Kennerley for a book project.

After we’d spent a few days on the sorts caster making letters, Jim asked if I wanted to make my own type- and I jumped at the chance! It’s easy to make a polymer plate with a custom design from a digital file, but there is something special about having your very own metal type.

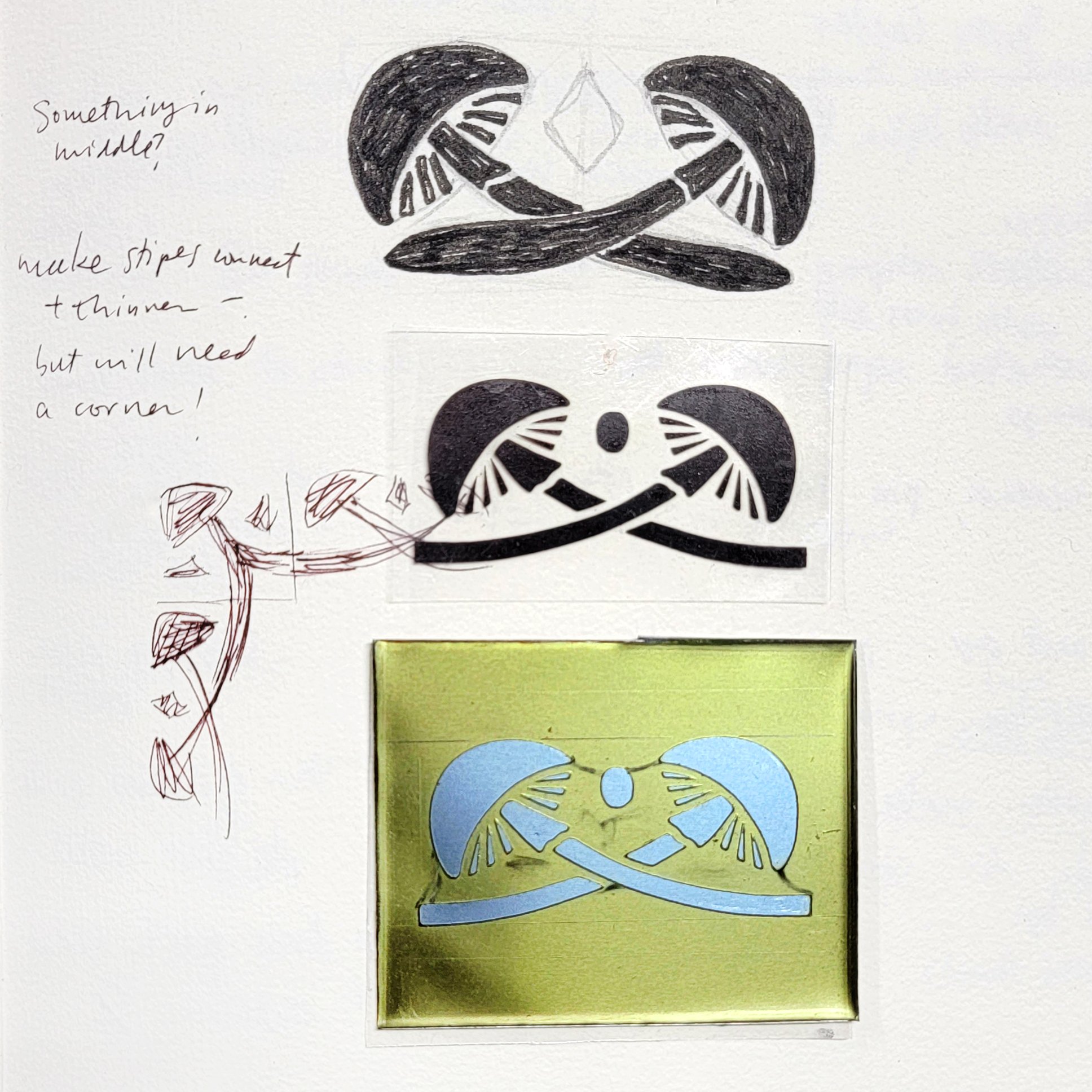

We started with my sketch, based on one of my favorite subjects. I traced and finessed the image in Illustrator to create a scaled vector version of the final art.

We printed a positive transparency at 5 times the final size, and exposed a polymer plate pattern on a home-made exposure unit. The pattern is the reverse of a printing plate–the image is sunk down into the plate instead of being raised up.

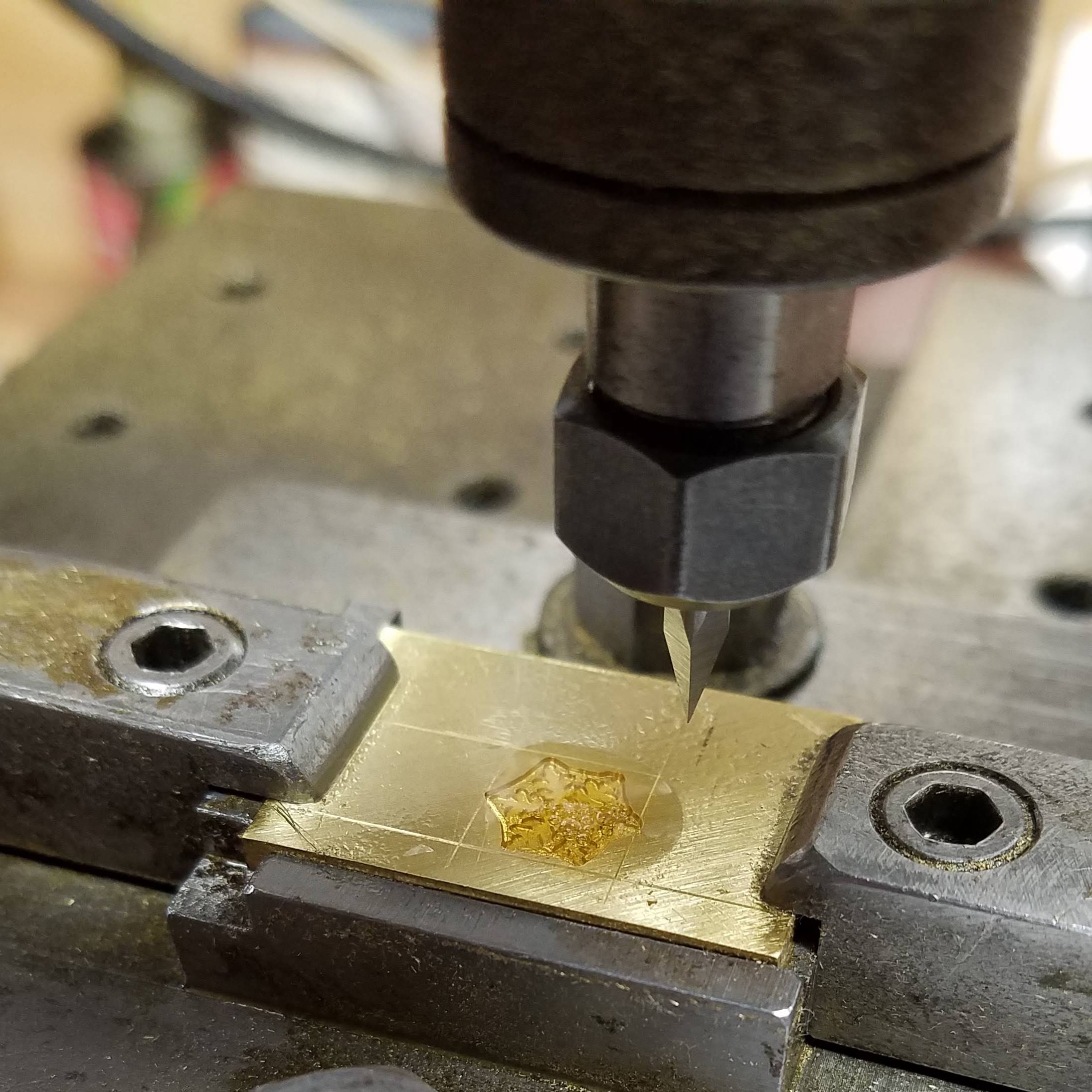

The pattern is mounted on one side of the Preis pantograph engraver, and a flat brass mat is locked into place under the cutting bit. The tracer moves inside the sunken pattern image, and moves the cutter across the brass mat at a reduced scale. Jim made cutter bits that have a tip measuring .003” (or so), to get the finest detail.

The mat is engraved in a series of shallow passes to get to the final depth of .050”. This mat can fit in a Thompson caster, or the Monotype Sorts caster.

The mat is mounted in a holder on the casting machine, and the proper size mold is installed.

The mat must be aligned so the type itself fits correctly on the body, and the engraving must be perfect so the type is exactly type high.

Once all the adjustments are made, the machine can cast hundreds of sorts per hour, by pumping the hot type metal into the mat and pushing out each piece of type. Some designs hang off the edge of the type, so each piece must be “rubbed” against a file to remove the overhang. Then, it’s ready to print!

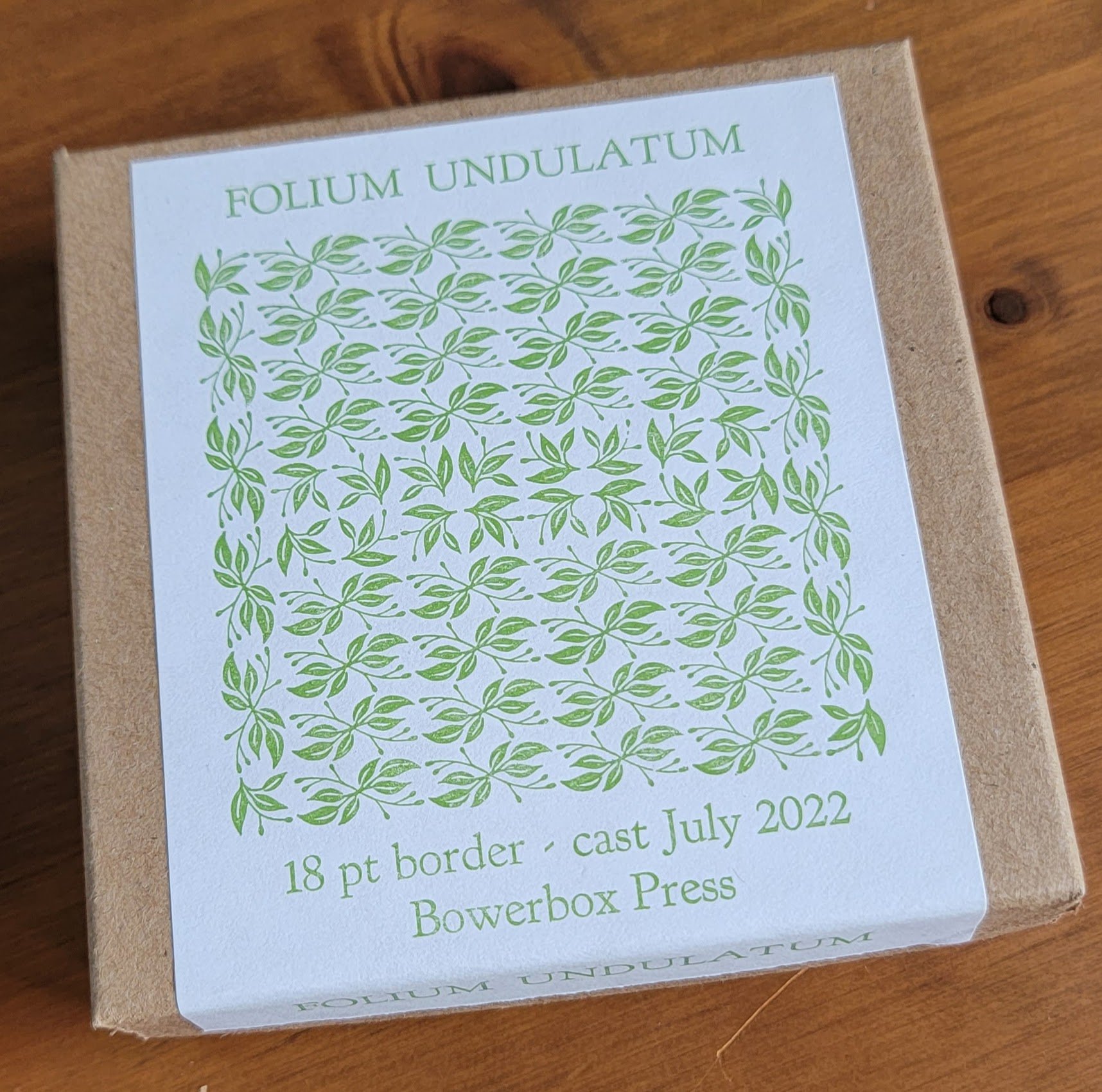

I have truly enjoyed learning how to cast type and how to create new designs, and am proud to have made the Amanita border, a set of snowflakes, and the Folium Undulatum border so far. I hope to continue making new designs and offering brand new type for printers to enjoy.

Check out Val’s work over at Bowerbox Press.